Test Solutions Partners

Moog and Savery Hydraulics - Forging the Future of Structural Testing

Advancing Structural Testing Through Expert Collaboration

Moog and Savery Hydraulics, leaders in their respective fields, partner to offer a superior range of test systems for Structural Testing.

Moog’s industry-leading expertise in Test Controllers and Simulation, paired with Savery’s specialised knowledge in Servo-Hydraulic Actuation, provides customers with state-of-the-art technology and outstanding performance.

Our long-standing partnership has been cemented through years of significant contributions to structural testing in the aerospace, automotive and wind energy sectors.

Together, we deliver not only technologically advanced and reliable solutions, but also ensure a seamless integration process. Our combined efforts are characterised by a deep commitment to excellence and a comprehensive approach to meeting the diverse needs of our customers.

Comprehensive Test Solutions Across Industries

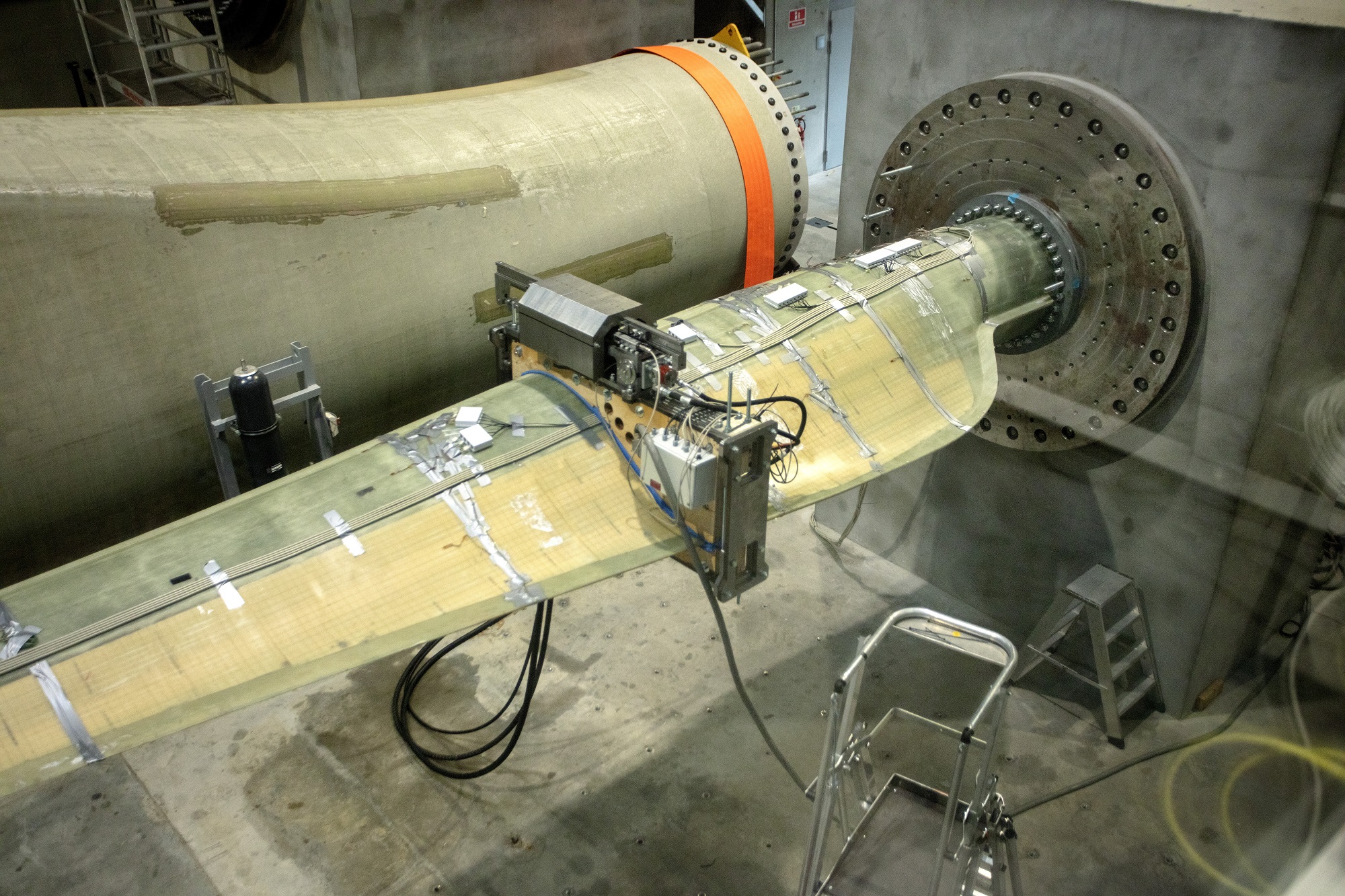

Aerospace: Testing ranges from individual components to entire structures, including full wings, fuselages, and undercarriages.

Automotive: Services extend from bed plate component testing to intricate multi-axis test rigs, encompassing dynamic battery testing.

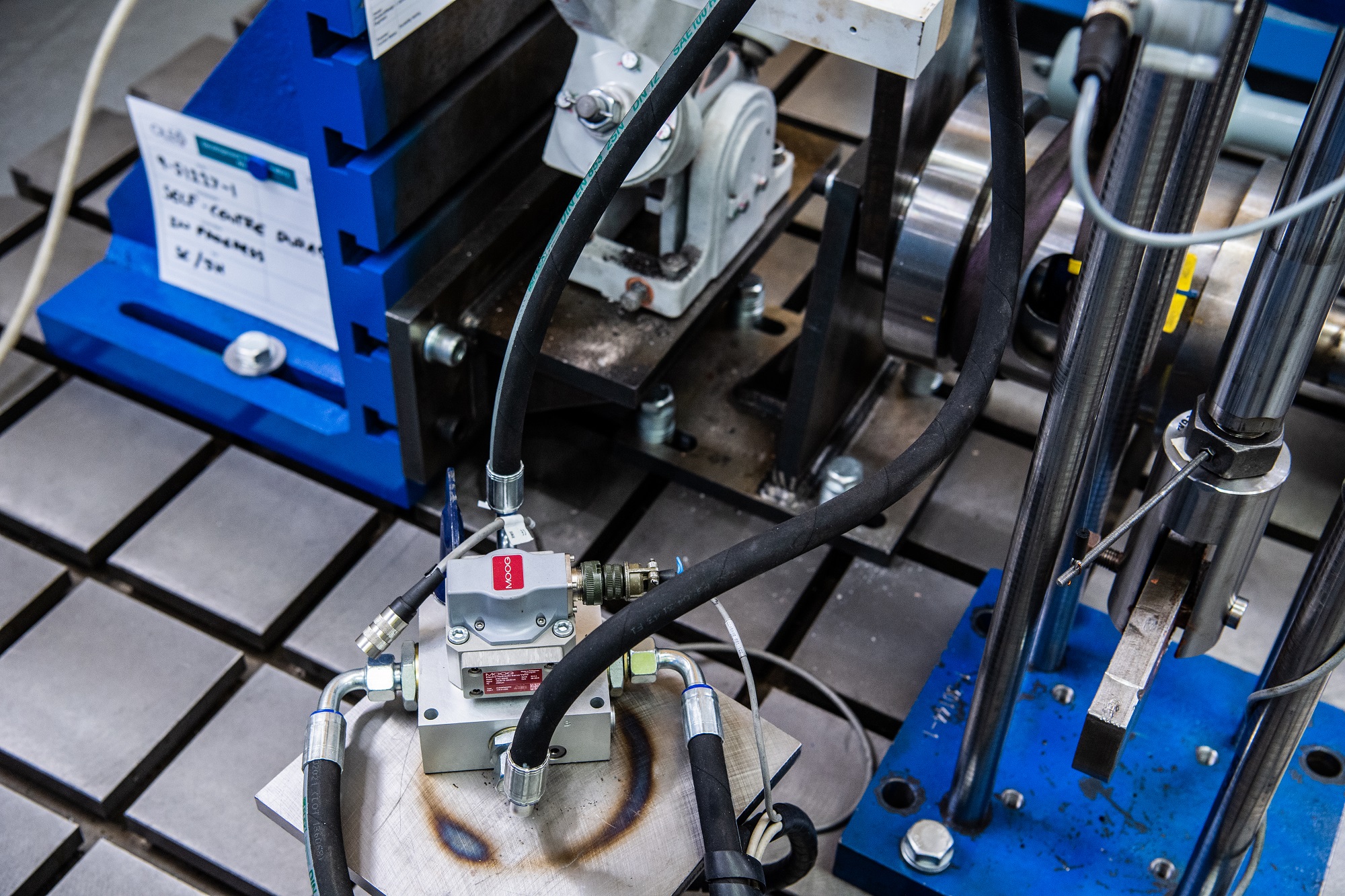

Renewable Energy: Expertise in installing wind turbine blade testing systems, catering to both static and dynamic testing, from prototype development blades to large-scale offshore turbines.

Research & Development: Provision of general test equipment for developmental testing and bed plate work, serving both research and qualification testing needs.

Mechanical Solutions: Infrastructure support for testing mechanical solutions.

Civil Engineering: Testing services for civil engineering applications, ensuring robust infrastructure development.

Total Project Support: From Concept to Completion

Comprehensive Systems Analysis: We meticulously review test requirements, considering both static and dynamic loads, frequencies, amplitudes, control systems, data logging, and load abort scenarios.

Simulation for Perfection: We have developed comprehensive, field proven analysis and simulation tools to enable our engineers to model system performance at the design stage.

Collaborating with the Customer: Our designs are iteratively refined to balance safety, reliability, viability, cost effectiveness and efficiency to minimise environmental impact.

Dynamic Project Planning: A dedicated planning manager oversees live project plans, integrating work packages, customer checkpoints, and assigned responsibilities.

Consistent Communication: We hold regular, documented meetings to keep all parties informed throughout the contract duration.

Detailed Installation 3D Models: Comprehensive installation and civil drawings are provided to facilitate civil contractors when needed.

Equipment Installation: Expert installation of hydro-mechanical, electrical, control, and data capture systems.

Rigorous Testing & Commissioning: We conduct thorough pressure testing and flushing, followed by meticulous system commissioning.

Customer Empowerment: Demonstrations and training sessions are provided to empower customers with the knowledge to utilize the systems effectively.

Long-Term Service Commitment: We offer full life service level packages to ensure the longevity and performance of the complete system.

Modular Test Solutions : Building Blocks for Customised Excellence

Specialised Power Units: Designed explicitly for test duty cycles.

Control Systems: Power unit motor control and PLC equipment with seamless integration to the test controller.

Hydraulic Service Manifolds: A versatile range of manifold to suit various applications.

Accumulator Stands: Equipped with safety manifolds to protect operators and test specimen, meeting and surpassing PED retirements.

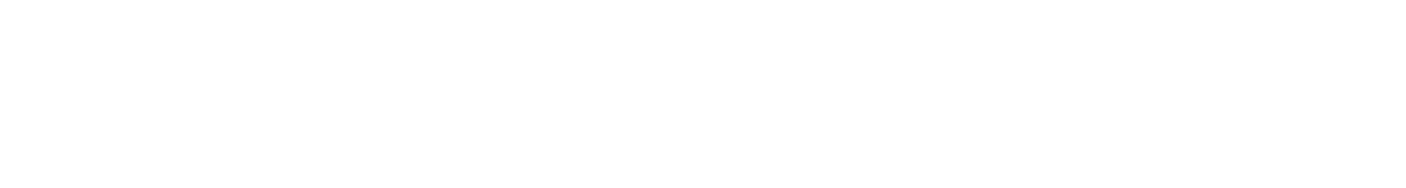

Actuators: A spectrum of low friction polymer bearing actuators, including essential components like position transducers, load cells, and differential pressure transducers.

Hydrostatic Actuators: Featuring position transducers, load cells, and differential pressure transducers for precise control.

Rotary Servo Actuators: For dynamic and accurate rotational movements.

Load Abort Manifolds: Both passive and active designs for safety and control.

Servo Valves: An extensive range of analogue and digital precision valves. Moog Closed Loop Servo-Controllers: With specialised software for automotive and aerospace applications.

Data Acquisition: Fully synchronised with the closed loop control system for real-time monitoring.

Safety and Energy Management: Adhering to ISO 13849 standards and focusing on efficient energy use.

Remote Monitoring: Cloud-based access via an app for 24-hour hydraulic performance monitoring and remote diagnostics.

Moog Global Support

Our commitment to keep your motion control components and systems running at peak performance by providing responsive repair and O&M support. Around the globe in 24 countries, local teams of trained Moog technicians are on standby with the services you need from express repairs to exchange programs, and on-site technical support