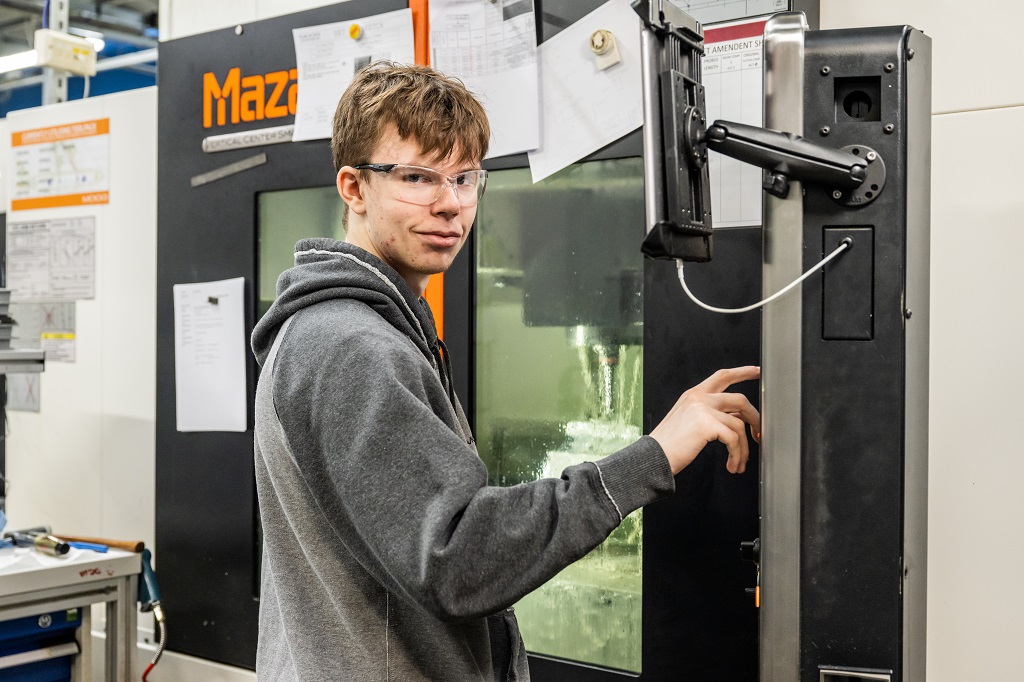

Apprentice Profile: Bert P

As an Apprentice Engineering Technician, Bert works predominately in the machine shop.

“At the moment, I usually laser engrave parts for identification, load metal bodies onto pallets or hone holes to a fine degree of accuracy. Loading bodies onto pallets readies them for processing in the WorkPartner machine, which uses programs and special computer chips to create slots, holes and fine cuts to parts. It uses a charged wire and electrodes to electronically cut metal, which allows for much more precise manufacturing. Honing holes requires a lot of time and care. Each part must be loaded into the Sunnen honing machine and the tool must be adjusted with any inaccuracies,” Bert said.

He chose Moog for his apprenticeship based on feedback from friends and family, who recommended the company to him.

“Working at Moog has helped me to think about the future as well – I can see myself working hard on higher qualifications and seeking different opportunities in the company,” Bert said.

In particular, the friendly working environment of the machine shop has really helped Bert to grow in his new career, and he’s met some great colleagues as part of his team.

“Although there hasn’t been one standout moment from my time at Moog so far, I’m proud of how I am adapting to different environments overall,” Bert said. “I was a very introverted person for a long time but I feel Moog has let me break out of my shell and be better in that regard.”

Careers at Moog

At Moog we’re always looking for great people to join our organisation. Take a look at our global opportunities and submit your application to join our Moog team.