Hydraulic Test System Upgrade for Aircraft Seat Test Rigs

Safran Seats - Cwmbran - Wales

Safran Seats is a global leader in aircraft seating solutions, with over one million seats in service across major airline fleets, providing seating for passengers and crew, across commercial aircraft and helicopters – tailored to the diverse needs of major airlines and manufacturers. To enhance test performance and reliability, Safran Seats collaborated with Moog and Savery Hydraulics to implement a major upgrade of its hydraulic test infrastructure.

The Challenge

Safran’s test facility in Cwmbran included two static test rigs used for static testing of aircraft seats. These rigs utilised manually operated valves to vary the force that the hydraulic cylinders produced. The legacy hydraulic systems were in need of modernisation, with improved documentation and functionality core to the requirement.

The Solution

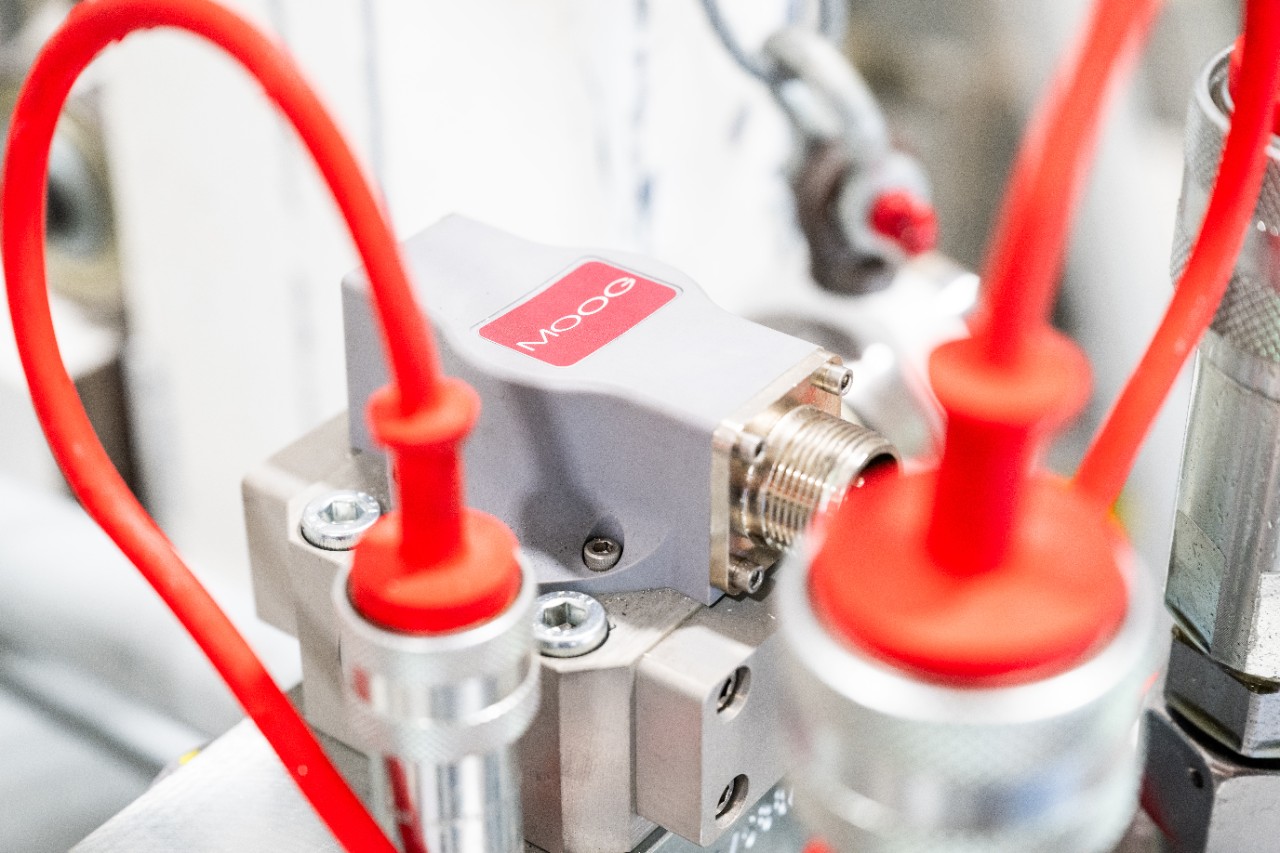

Moog proposed a comprehensive upgrade package, including the design, manufacture, installation, and commissioning of a modern closed-loop servo hydraulic system tailored to Safran’s requirements.

Moog and Savery delivered the system with full installation, commissioning, and operator training, ensuring a smooth transition and continued high-performance testing.

The Result

The Safran Test facility is now able to offer high performance precision structural testing with three independent test cells to address the needs of their customers.

Operators can configure, control, and monitor tests from dedicated workstations in each cell, improving usability and efficiency.

The facility is backed by a maintenance and support contract, including annual calibration, reinforcing the long-term partnership between Moog and Savery Hydraulics.

The Benefit - The Voice of our Customer

"Originally, we had limited the operation to a single test rig control, with a unified key system to transfer control. Now, we’ve progressed to a setup where each of the three test rigs can be controlled independently and most importantly, simultaneously. That’s a significant leap forward. This flexibility is unmatched within Safran systems, impressing internal and external stakeholders, and laying a strong foundation for future developments.”

Aran Taylor, Head of Test, Safran Seats GB

Moog Global Support

Our commitment to keep your motion control components and systems running at peak performance by providing responsive repair and O&M support. Around the globe in 24 countries, local teams of trained Moog technicians are on standby with the services you need from express repairs to exchange programs, and on-site technical support