Upgrade of Structural Test Laboratory at TA Savery, UK

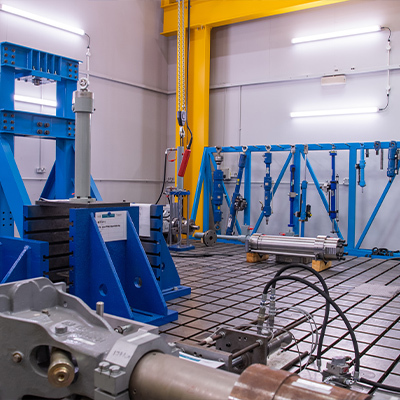

New generation Moog Test Controller installed to support global rail testing

- Pulp and Paper Mills

- Wimbledon Roof

- DTU Blade Testing

- Shinkansen Rail

- Stewart F1 Racing Car

- IIT HyQ Quadruped Robot

- James Fisher Nuclear Hydraulic Arm

- Lockheed Martin Tank Turret Tester

- Powergen Actuator Repair

- Savery Rail Test Facility

- Honda Wind Tunnel

- PAS Valves for F1

- Composite Aircraft Wing

- Aircraft Structural Test - Facility Enhancement

- Helicopter Airframe

- Safran Seats

Modernisation of Existing Testing Facility

In November 2020, the UK Government published a Ten Point Plan for a Green Industrial Revolution, and Point 5 covers Green Public Transport. Integral to this is the continued electrification of UK railway lines and the expansion of rail routes. With such ambitious plans to upgrade the UK network dating back to 1830, coupled with a growing rail industry worldwide, expanding traffic volumes, and advancing rail speeds, it was critical that the ISO 17025 accredited test laboratory already established at TA Savery in Coventry, UK was modernized to enable a more efficient testing capability, helping modern railway networks meet standards of operability, maintainability, and low life cycles costs.

Rail projects often require unique train designs due to variations in infrastructure, environment, regulations, and operating practices. Neither time nor cost permits prototype trains to conduct crash testing, so standards such as EN15227 look towards simulation, correlated against physical tests to verify performance. At the same time, crash energy management systems are becoming increasingly complex, incorporating anti-climbers, buffers, couplers, and crush elements. TA Savery group provides sophisticated simulations of collisions to evaluate crash energy management systems along the train and energy absorption devices correlated by over thirty years of testing, accredited since 2013 to ISO17025 and audited by UKAS (UK Accreditation Service).

The Challenge

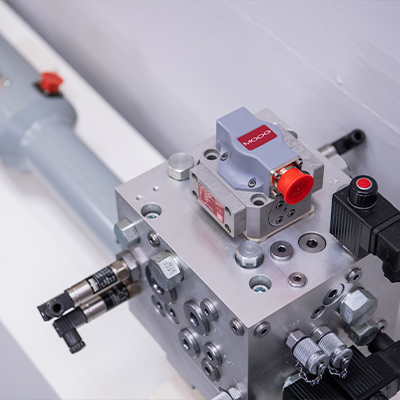

As a major supplier of rail and lift buffer components, testing is an essential part of the TA Savery group’s offering. TA Savery’s existing test facility was tired and required ongoing human intervention to keep tests running, which was time-consuming and inefficient, so a major upgrade to cope with the increase in both the volume and complexity of tests were required.

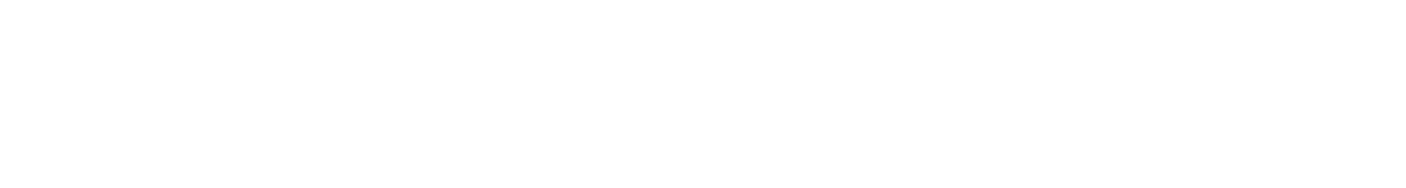

TA Savery’s project team planned an ambitious new Structural Test Laboratory, with the capability to offer characterisation, strength, and fatigue testing to 10,000,000 cycles, based around a 6m x 6m bedplate, 5 tonnes fixture.

The Solution

The Moog team worked in close partnership with the TA Savery Engineers to create the optimum test laboratory with considerable time spent by both parties in detailed discussions around the scope and ultimate implementation of the solution. Flexibility in configuration and the ability to run several different tests simultaneously was the main objective.

The Result

TA Savery can now confidently offer repeatable accurate testing using industry standard hardware and software, together with the back-up of Moog expert engineering to provide a comprehensive test house capability attracting test work packages from both internal areas within the TA Savery organisation and test work from external customers.

The Benefit

The Lab Manager said “We used to have to stay with the test in the past, with a hand on mechanical levers, which was very labour intensive, keeping a watchful eye on the tests. Leaving a test to run over the weekend was not an option. Now we can go home knowing that the testing is safe and predictable enabling us to complete the test cycle in less time, increasing our productivity."

Moog Global Support

Our commitment to keep your motion control components and systems running at peak performance by providing responsive repair and O&M support. Around the globe in 24 countries, local teams of trained Moog technicians are on standby with the services you need from express repairs to exchange programs, and on-site technical support