Aerodynamic Vehicle Testing for Production Vehicles and Race Cars

Honda Automotive Laboratories of Ohio (HALO) Facility

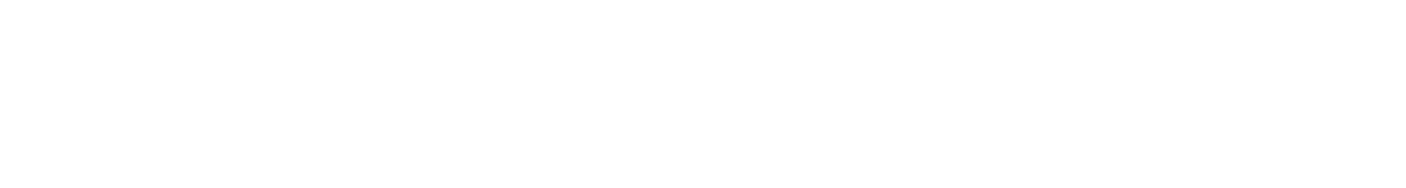

In March 2022 Honda opened its $124 million state-of-the-art wind tunnel facility, ushering in a new era of development testing capabilities for Honda and Acura products, as well as the development of racing cars from pinnacle racing in IndyCar and next generation LMDh sports cars to commercial racing programs.

The new Honda Automotive Laboratories of Ohio (HALO) facility, located at the independent Transportation Research Center Inc. (TRC) in Central Ohio, is one of the world’s most advanced wind tunnels, with three separate state-of-the art testing functions — aerodynamics, aeroacoustics, and racing — in one location.

Honda created the multifunctional HALO facility to reinforce its commitment to developing fuel-efficient and fun-to-drive vehicles. One of the most advanced of its kind anywhere, the wind tunnel uses a unique interchangeable modular ground plane system capable of aerodynamic vehicle testing of production vehicles and race cars. The tunnel can generate wind speeds of more than 190 miles (306 km/h).

The Challenge

Moog was approached by Honda in 2019 to provide an active ride height system incorporating a revolutionary stability control function.

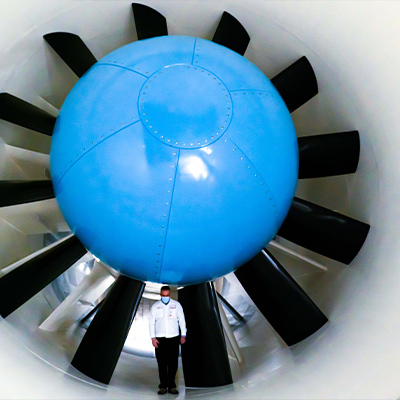

The system needed to provide actuation and control of the ride height of a test vehicle undergoing aerodynamic testing in the new wind tunnel environment and a separate vehicle in the setup area. Moog’s system replaces the conventional on-car suspension, which presents a new challenge in that a vehicle suspended purely on its tires can experience pitch oscillations during high-downforce test conditions. These oscillations generate unrepresentative test results and preclude running the vehicle at very low ride heights because of the danger of contacting the moving belt.

Moog was chosen due to its extensive experience in active suspension in motorsport – developed initially for Team Lotus and Williams GP Engineering during the 1980s.

The Solution

The Moog team supplied a turn-key servo-hydraulic control system that can be installed in a variety of vehicles. Moog’s bespoke software is designed to control the ride height, pitch, and roll demands and incorporate a high-speed damping system, preventing the car from oscillating at high downforce levels – enabling precise control of ride height, pitch, and roll of the vehicle during aerodynamic testing.

The Result

The entire project was worked on during the COVID-19 pandemic, lending itself to increased pressures. Factory acceptance testing, usually carried out in person, was undertaken over the internet by Moog, Honda, and Cosworth while the US border was closed. Full commissioning was launched when the border was opened for essential business travel. The Active Ride Height System is now fully operational in the wind tunnel environment, with continued support should Honda require it.

The Benefit

Honda’s new wind tunnel can help to optimise the aerodynamic performance of race cars competing in various motorsport disciplines, especially the Indy 500. The ride height system provides a means to achieve representative test conditions at varying ride height, pitch, and roll without the need to make time-consuming modifications to the suspension.

Moog Global Support

Our commitment to keep your motion control components and systems running at peak performance by providing responsive repair and O&M support. Around the globe in 24 countries, local teams of trained Moog technicians are on standby with the services you need from express repairs to exchange programs, and on-site technical support