The Technological Challenge

In collaboration with SCX Special Projects & Fairfield Controls

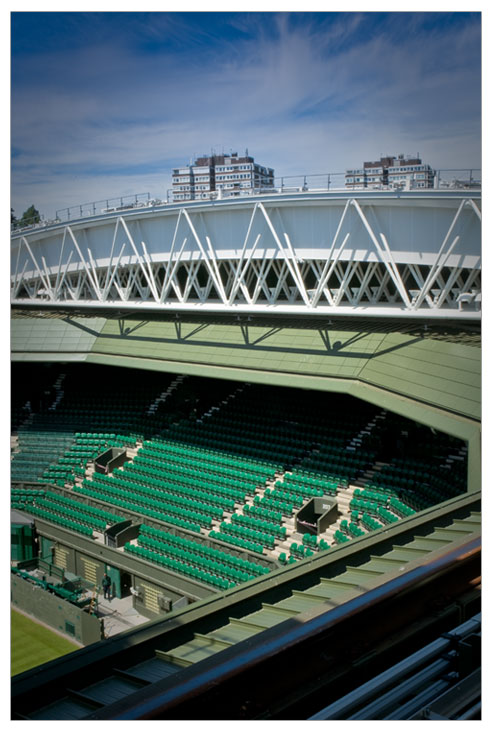

A roof that would operate securely, quietly, speedily, safely and accurately, be completed by the 2009 Championships, and be under the scrutiny of the entire world.

Challenge 1

Provide electric motion control for a retractable roof on a building dating from 1922.

Challenge 2

Safely move 1,000 tonnes of steel above 15,000 spectators with the touch of a button.

Challenge 3

Occupy minimal space, enabling sunlight & ventilation to reach the pitch below

Watch the Case Study Video

Key Features of the Wimbledon All-Electric Retractable Roof

All-electric concertina retractable roof.

Metal trusses support a translucent industrial fabric.

Trusses supported by end arms and set into precise motion by electric actuators which form a structural yet moveable part of the roof.

Truss ends are supported by a wheeled carriage or 'bogie' which moves along a track positioned on the fixed roof.

Moog Global Support

Our commitment to keep your motion control components and systems running at peak performance by providing responsive repair and O&M support. Around the globe in 24 countries, local teams of trained Moog technicians are on standby with the services you need from express repairs to exchange programs, and on-site technical support